In fact, only about 66% of sun light is absorbed and coupled with solar panels working best only when the sun shines directly upon them, this all adds up to nominal efficiency. To make up for lost efficiency, the large solar arrays use energy consuming mechanical positioning to follow the sun across the sky. However, there should be a better way, right?

Where is that amazing American intelligence that put men on the moon and brought them home safely? Well EHW is happy to report that our American astuteness is alive and well at Rensselaer Polytechnic Institute in Troy, New York.

From all the details EHW has seen so far, we are hopeful that Doctor Shawn Lin and his colleagues at Rensselaer have a 7 layer solution. A new antireflective coating has been nanoengineered to increase the amount of sunlight captured by solar panels across the entire color spectrum and from any angle! Yes, any angle despite the position of the sun in the sky.

Due to this coating enhancing the antireflective properties of the layer below the solar cells will be inundated with 96.2% of rays from the sun. The added bonus is light being trapped and absorbed from all angles. Thus there is a 30% increase in efficiency.

This data sounds excellent, but EHW initiated correspondence with Rensselaer Polytechnic Institute and Dr. Lin's office to get answers to the following additional questions:

* Can this coating be applied to current solar panels already in use?

* Does the coating degrade over time and lose efficiency?

* How does the coating stand up to all the elements?

* When will the manufacturing of this coating be feasible?

Dr. Lin's office replied with the following answers:

The coating cannot be applied to already-installed solar panels. The coating must be applied at the time of manufacturing. EHW also learned that the coating does not degrade, but is somewhat fragile. The research team, led by Dr. Lin, is looking into ways of making the coating more robust and better able to weather the elements. End results, Dr. Lin does not believe we the people will have to wait the proverbial ten years for this product to become a reality in our lives. In fact, Dr. Lin expects a product based on this new technology will be on the market within three years.

"We are working to determine the best way to bring this new technology to market. We are exploring partnerships and licensing arrangements, but have not decided on exactly how to proceed. But as far as bringing the product to market, I think we're talking near-term, in the next 2-3 years, rather than long-term. In our research, the next step moving

forward will be investigating how to make our antireflective coating more robust.

The antireflective coating requires multi-layer coating, which is slightly more complex than the typical single-layer coating. However, the thickness of each individual layer does not need to be precise to, say, within 10 percent. This makes the manufacturing easier.

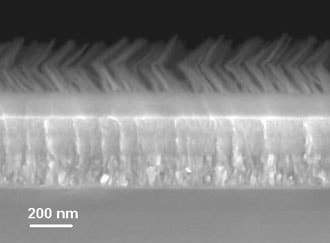

The antireflective coating also requires low-index layer (i.e. n<1.1-1.2). Currently, we use a special technique, called oblique angle deposition, to grow porous nanorods to accomplish the low-n requirement. The nanorods can be fragile. Further research will be needed to either find a way to better protect the nanorods, or to develop or use a porous thin film that is more robust.

The economics of modern day solar cell depends largely on the thickness of the substrate (500-1000 micrometer) and the processing cost for making the junctions. Our antireflective coating is made of oxide materials (Silicon dioxide and Titanium oxide) and has a thickness of 0.7-1 micrometer. The deposition is based on a fairly simple technique that is compatible to most standard solar cell manufacturing. The additional cost for incorporating our antireflective coating should not exceed 2 percent to 4 percent of the original cost of producing the existing solar cell.

Our equipment can handle a 2-inch wafer. The process may be easily scaled up to a 6-12 inch process." - Shawn Lin

Environmental Scientist

International Sustainability and Energy Consultant

Contribute your comments!