Ancient Roman Concrete 2K Years Old

Ancient Roman Concrete 2K Years Old Now since some calculations say that manufacturing concrete today contributes 8% of carbon emissions world wide and our modern concrete can crumble within decades, especially when exposed to eroding environmental conditions, longer lasting concrete will help our environment by lowering carbon emissions.

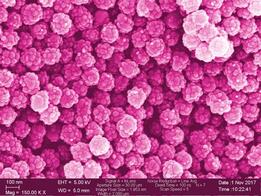

So why does Roman concrete last thousands of years? The answer came this year in a 2023 study that used reverse engineering on samples of concrete made by the ancient Romans. A team of investigators from MIT and laboratories in Italy and Switzerland, discovered ancient concrete-manufacturing strategies that incorporated several key self-healing functionalities. One of several papers was published in the journal Science Advances.

First, everything previously assumed about ancient Roman concrete is wrong:

- The one magic ingredient was pozzolanic material such as volcanic ash

- The various small particles in the concrete was due to poor mixing practices or just being sloppy

- The slaking process using water and lime to form a highly reactive paste material made the difference

Under high-resolution with multi-scale imaging and chemical mapping techniques, researchers gained new insights into the potential functionality of "Lime Clasts" and the slaking process was not a contributing factor. Studying samples of ancient concrete, the small white particles were forms of calcium carbonate. Under spectroscopic examination it was determined they had been formed at extreme temperatures. This was the key to the super-durable nature of Roman concrete and the hot mixing produced compounds that would not otherwise form. Additionally, this increased temperature significantly reduces curing, setting and construction times.

Rome's Trevi Fountain With Water via 2K Year Old Aqueduct

Rome's Trevi Fountain With Water via 2K Year Old Aqueduct To test this mechanism, which was responsible for the durability of the Roman concrete, samples of hot-mixed concrete were made and then deliberately cracked. Water was sent through the cracks and within two weeks the cracks had completely healed. As a result of these successful tests, work is being done to commercialize this modified concrete material.

If commercializing is successful, this "old made anew" concrete material will help improve the durability of the 3D Printing of concrete homes for the poor, (see previous GTG blog post of this topic) save money in production and time, less concrete manufacturing due to this concrete having a longer lifespan, and help reduce greenhouse gas emissions.

Bill Lauto, at GoingTrueGreen.com

Environmental Scientist

International Sustainability and Energy Consultant

Contribute your comments!